Introduction

Mechanical design is the manner of designing and growing mechanical components and systems which can be utilized in a huge variety of merchandise. This includes the whole thing from small purchaser merchandise like smartphones and home appliances to larger products like automobiles and business equipment. Mechanical design involves using engineering ideas, substances science, and advanced software program gear to create strong and green mechanical structures.

The significance of mechanical layout in product improvement can’t be overstated. Good mechanical design is essential for creating merchandise which are secure, reliable, and carry out as anticipated. It is also important for ensuring that products are manufactured correctly and fee-efficiently.

In brand new competitive marketplace, businesses have to continuously innovate and enhance their merchandise to live in advance of the competition. Good mechanical design is a key thing in product innovation, because it lets in companies to create merchandise which are greater efficient, extra dependable, and more value-powerful than their competition.

Overall, mechanical design is a crucial thing of product improvement, and it’s far important for businesses that want to succeed in today’s rapid-paced and aggressive enterprise surroundings.

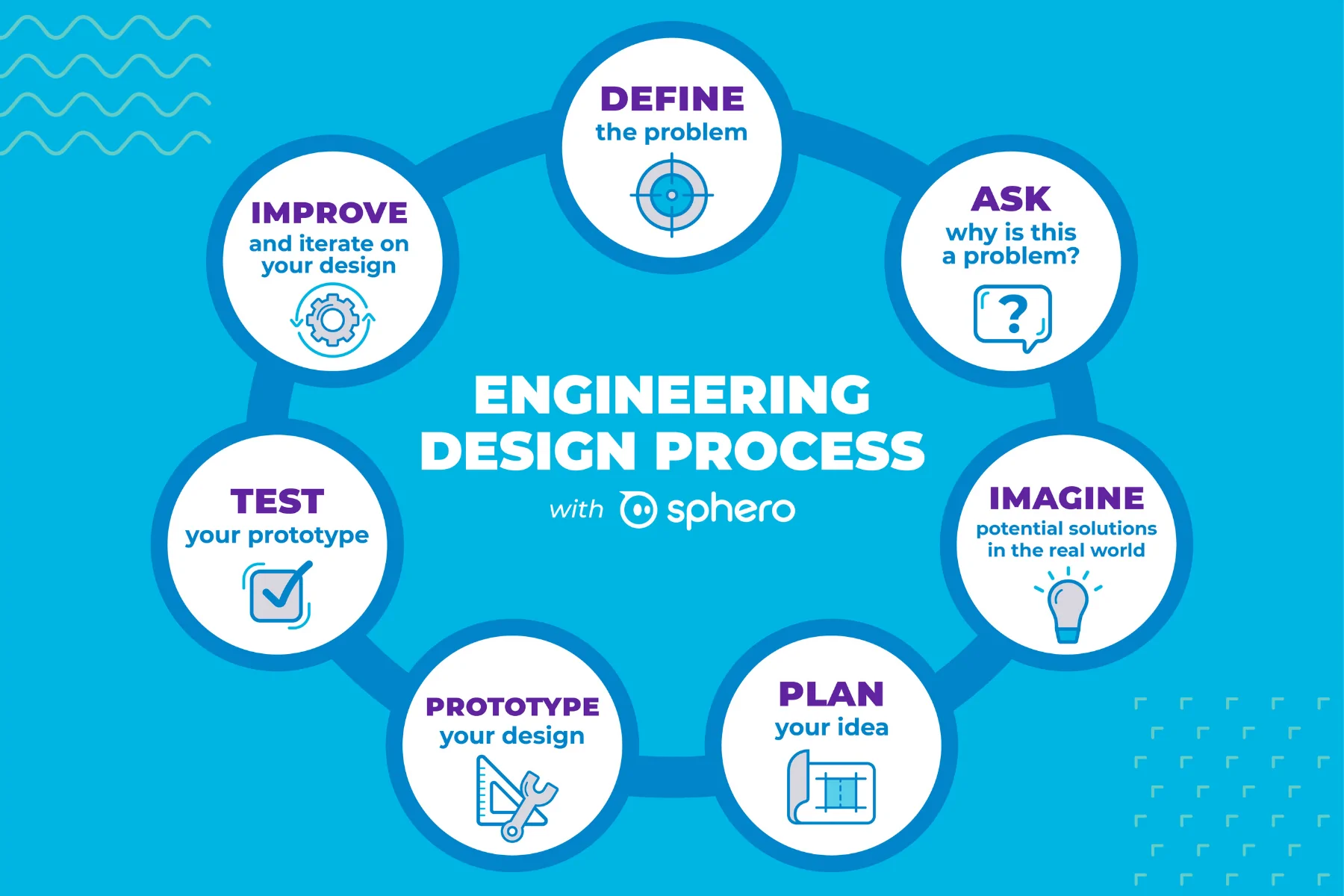

The Process of Mechanical Design

Mechanical design is a complex and iterative method that entails several key steps. Here are some of the key steps involved in mechanical design:

- Define the Problem: The first step in mechanical design is to really outline the problem that the layout is meant to resolve. This entails identifying the consumer needs, constraints, and specifications as a way to guide the layout manner.

- Brainstorming and Concept Development: Once the trouble has been defined, the next step is to brainstorm and expand principles for the mechanical design. This includes generating a huge variety of ideas and evaluating them primarily based on elements like feasibility, price, and performance.

- Design and Modeling: The 0.33 step is to create an in depth design of the mechanical gadget using superior software tools like CAD (Computer-Aided Design) software program. This step includes growing 3-d models and simulations of the mechanical gadget to assess its performance and become aware of any capacity problems.

- Prototype Development and Testing: After the layout has been created and modeled, the next step is to create a prototype of the mechanical device. This lets in engineers to check the layout and discover any issues that want to be addressed.

- Design Refinement: Based on the consequences of the prototype testing, the mechanical design is subtle and improved. This may additionally involve making modifications to the design or choosing unique materials to enhance performance or reduce prices.

Key considerations for the duration of Mechanical Design:

In addition to the key steps concerned in mechanical layout, there are numerous key concerns that should be taken into consideration. These encompass:

- Performance: The mechanical design ought to be optimized for overall performance, taking into consideration factors like velocity, torque, and power.

- Reliability: The mechanical system have to be designed to be reliable and sturdy, even in harsh operating conditions.

- Safety: The mechanical design should be safe for customers, with appropriate safeguards to save you harm or harm.

- Cost: The mechanical layout need to be fee-powerful, with a focus on decreasing material and production fees without compromising overall performance or fine.

Overall, mechanical layout is a complex and iterative method that requires cautious attention of a couple of elements. By following a scientific technique and specializing in key issues, engineers can create mechanical systems which can be green, dependable, and value-effective.

Benefits of Good Mechanical Design

Good mechanical design is important for developing merchandise that meet user needs and perform as anticipated. Here are a number of the key benefits of correct mechanical design:

- Improved Product Performance and Reliability: Mechanical design is important for optimizing the overall performance of merchandise. By designing mechanical components and systems that are green and reliable, engineers can create products that perform better and closing longer. This consequences in higher purchaser satisfaction and repeat business.

- Enhanced User Experience: Good mechanical design can enhance the consumer experience by growing merchandise which can be smooth to apply and operate. This can consist of capabilities like ergonomic layout, intuitive controls, and easy operation. A precise person experience is vital for building brand loyalty and setting up a competitive advantage.

- Cost Savings: Good mechanical layout can also result in value financial savings by way of reducing material and production fees. By optimizing the layout of mechanical additives and structures, engineers can lessen the quantity of fabric needed to produce a product, and streamline the manufacturing method. This results in decrease production costs and higher profit margins.

Overall, accurate mechanical design is important for creating products that meet consumer desires, carry out as anticipated, and are cost-effective. By that specialize in the key advantages of proper mechanical layout, engineers can create products which might be competitive, profitable, and sustainable.

Examples of Successful Mechanical Design in Product Development

Mechanical design plays a critical role in product development, and there are many examples of successful mechanical design in various industries. Here are two examples of products that have achieved success due in part to their exceptional mechanical design:

Case Study 1: Apple iPhone

The iPhone has become one of the most successful consumer products of all time, and its mechanical design has played a significant role in its success. The iPhone’s sleek and minimalist design has become an iconic symbol of modern technology, and its smooth and intuitive operation has won over millions of users worldwide.

The iPhone’s mechanical design is a key factor in its success. The device is designed to be slim and lightweight, with a smooth and responsive touch screen that is easy to navigate. The iPhone’s mechanical components are also optimized for efficiency and reliability, with a powerful battery that can last for hours of use.

In addition, Apple’s use of advanced manufacturing techniques like CNC (Computer Numerical Control) machining has allowed them to produce iPhones with tight tolerances and high levels of accuracy. This has enabled them to create products that are both aesthetically pleasing and functional, while also reducing manufacturing costs.

Case Study 2: Tesla Model S

The Tesla Model S is a luxury electric car that has received widespread acclaim for its exceptional performance and advanced features. The Model S’s mechanical design is a key factor in its success, as it enables the car to achieve impressive levels of performance and efficiency.

The Model S’s mechanical design includes features like a lightweight aluminum chassis, aerodynamic body styling, and a powerful electric drivetrain. These features allow the car to achieve a range of over 400 miles on a single charge, and accelerate from 0 to 60 miles per hour in as little as 2.4 seconds.

In addition, the Model S’s mechanical design includes advanced safety features like automatic emergency braking, collision avoidance, and adaptive cruise control. These features have helped the car to receive top safety ratings from organizations like the National Highway Traffic Safety Administration (NHTSA).

Overall, the mechanical design of the Tesla Model S has been a critical factor in its success, enabling it to achieve high levels of performance, efficiency, and safety.

Common Challenges in Mechanical Design and How to Overcome Them

Mechanical layout is a complex method that calls for cautious planning, attention to element, and a thorough knowledge of the product necessities. Despite the first-class efforts of engineers, there are common demanding situations which could get up in the course of the mechanical design method. Here are 3 not unusual challenges in mechanical layout and the way to conquer them:

- Design for Manufacturing: One of the most important challenges in mechanical layout is designing for manufacturability. A product can be nicely designed on paper, but if it can’t be manufactured correctly and price-efficiently, it may not be possible. To overcome this task, engineers need to take into account the producing manner early in the layout method. This includes deciding on substances that are smooth to work with, minimizing the wide variety of parts, and the usage of widespread production techniques wherever viable.

- Material Selection: Selecting the right substances for a mechanical layout is crucial for ensuring product overall performance and reliability. However, with so many substances available, it may be challenging to pick out the right one. To triumph over this challenge, engineers need to consider factors just as the product’s working conditions, the mechanical residences required, and the cost of the fabric. They ought to also recall environmental elements, consisting of the material’s impact on the environment and its recyclability.

- Environmental Considerations: As customers become extra environmentally conscious, there is growing pressure on groups to lay out products that can be sustainable and environmentally friendly. This can be a challenge for mechanical design, as materials and manufacturing tactics which might be sustainable won’t be as simply available or fee-powerful. To conquer this task, engineers need to consider the environmental effect in their designs from the start. This consists of selecting materials that are renewable or recyclable, designing for strength efficiency, and the usage of sustainable manufacturing processes.

By addressing those not-unusual challenges in mechanical layout, engineers can create merchandise which can be dependable, efficient, and sustainable. With cautious planning and attention to detail, mechanical layout can be a worthwhile and successful technique.

Future Trends in Mechanical Design

As technology maintains to conform, mechanical design is likewise evolving. Engineers are exploring new strategies and technology to create products that are more green, sustainable, and related. Here are 3 destiny trends in mechanical design:

- Additive Manufacturing: Additive manufacturing, also referred to as three-D printing, is a hastily evolving technology that is transforming the manufacturing industry. With additive manufacturing, engineers can create complicated geometries and decrease the variety of parts required, main to greater green and price-powerful designs. Additive manufacturing additionally enables speedy prototyping and customization, allowing engineers to quickly iterate and refine their designs.

- Integration with IoT and AI: The Internet of Things (IoT) and Artificial Intelligence (AI) are remodeling the manner we engage with products. By integrating mechanical designs with IoT sensors and AI algorithms, engineers can create products that are greater intelligent and attentive to person desires. For instance, a mechanical layout can be integrated with IoT sensors to provide actual-time tracking and diagnostics, whilst AI algorithms can optimize the product’s overall performance and electricity efficiency.

- Sustainability: With growing worries approximately the effect of merchandise at the environment, sustainability is turning into an crucial attention in mechanical layout. Engineers are exploring new substances and manufacturing methods which might be greater sustainable and environmentally pleasant. For example, bio-based totally substances like bioplastics and biomimicry are being used to create merchandise which are biodegradable and non-poisonous. Sustainable production strategies, which include energy-green machining and closed-loop production, are also being advanced to lessen waste and strength consumption.

In end, mechanical layout is a continuously evolving subject, and engineers need to live up to date with the brand new developments and technology. By embracing additive manufacturing, integrating designs with IoT and AI, and prioritizing sustainability, engineers can create merchandise that are more green, clever, and environmentally friendly.

Conclusion

Mechanical design is a critical aspect of product development that can have a significant impact on product performance, reliability, and cost. By following a well-defined process, considering key design considerations, and addressing common challenges, engineers can create products that meet the needs of their customers and the market. Additionally, by embracing future trends in mechanical design, engineers can create products that are more efficient, intelligent, and sustainable.

In conclusion, the importance of mechanical design cannot be overstated. It is essential to ensure that products are designed to meet customer needs, are reliable, and are cost-effective to manufacture. By prioritizing mechanical design, companies can set themselves apart from the competition and create products that exceed customer expectations. As technology continues to evolve, it is essential for engineers to stay up-to-date with the latest trends and techniques to remain competitive in the marketplace.

In summary, mechanical design is a fundamental aspect of product development that should not be overlooked. It is the foundation on which products are built, and a well-designed product can be the key to success in today’s competitive marketplace. By prioritizing mechanical design, companies can create products that meet customer needs, are reliable, and are cost-effective to manufacture, while also embracing future trends in mechanical design to create more efficient, intelligent, and sustainable products.